When: June 24-26, 2025

Where: National Exhibition and Convention Center, Shanghai

Techik Booth: 51E05

Get ready to dive into the next generation of food processing and packaging at ProPak China & FoodPack China 2025, happening June 24-26, 2025, in Shanghai’s National Exhibition and Convention Center. At Booth 51E05, Techik will unveil its revolutionary ultra-high-definition equipment and smart solutions, redefining efficiency and precision in food production. Join us to explore how we’re paving the way for smarter, safer, and more sustainable food manufacturing.

When: June 24-26, 2025

Where: National Exhibition and Convention Center, Shanghai

Techik Booth: 51E05

Get ready to dive into the next generation of food processing and packaging at ProPak China & FoodPack China 2025, happening June 24-26, 2025, in Shanghai’s National Exhibition and Convention Center. At Booth 51E05, Techik will unveil its revolutionary ultra-high-definition equipment and smart solutions, redefining efficiency and precision in food production. Join us to explore how we’re paving the way for smarter, safer, and more sustainable food manufacturing.

Why Visit Techik?

Techik is at the forefront of transforming food production with intelligent, high-precision technologies. Our showcase at ProPak China 2025 will highlight innovative solutions across detection, sorting, grading, and analysis, empowering food manufacturers to achieve unmatched quality and operational excellence.

Key Applications

Precision Detection: From seal integrity to inkjet accuracy, shrink film quality, foreign contaminants, and weight verification.

Smart Sorting: Eliminate off-color, misshapen, or defective products with advanced texture and defect sorting.

Accurate Grading: Classify products by weight, shape, material, or appearance for maximum value.

In-Depth Analysis: Unlock insights with composition analysis for consistent quality.

Techik’s Game-Changing Solutions

1. Ultra-HD Bulk Material Inspection

For: Nuts, seeds, dried fish, edamame, and beyond.

Real-World Impact: Hazelnut processing – Pinpoints tiny contaminants like screen mesh, plastic, or shells, plus internal flaws like mold or insect damage.

Equipment: Ultra-HD Bulk X-Ray Inspection System

Crystal-clear imaging catches low-density and organic impurities.

Smart algorithms boost detection of subtle defects in products like hazelnuts or macadamias.

Multi-lane inspection and rejection minimize waste.

2. Dual-Energy Ultra-HD Analysis

For: Meat products tackling residual bones, fat analysis, and complex challenges like low-density or thin contaminants in frozen stacks.

Real-World Impact: Frozen chicken – Detects bones, fishbones, sand, and thin materials like aluminum or PVC.

Equipment: Ultra-HD Dual-Energy X-Ray Inspection System

High-accuracy detection with versatile product compatibility.

Built for durability and long-term reliability.

3. Ultra-HD Seal Inspection

For: Small to medium packaged foods in aluminum foil, metallized, or PE films.

Real-World Impact: Snack bags – Spots leaks, inclusions, wrinkles, and other seal issues.

Equipment: Ultra-HD X-Ray System for Sealing, Stuffing and Leakage

All-in-one inspection for seals, contaminants, defects, and weight.

Detects subtle issues like minor leaks, damaged seals, or insect contamination.

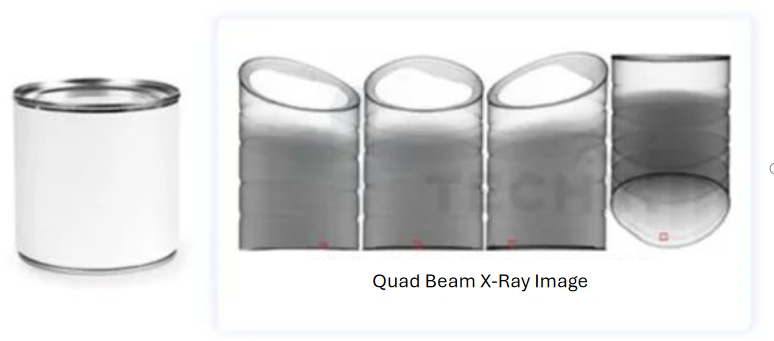

4. Multi-Angle Ultra-HD Bottle & Can Inspection

For: Beverages, condiments, canned powders, or luncheon meat.

Real-World Impact: Canned goods – Overcomes blind spots in tricky areas like can bottoms, screw caps, or pull-tabs.

Equipment: Ultra-HD Multi Beam X-Ray Inspection for Cans, Bottles and Jars

Fast, precise detection with complementary beam angles for thin contaminants.

Monitors line issues like congestion or fallen products, with alarms for defects or full bins.

5. Multi-Angle Ultra-HD Bulk Sorting

For: Frozen, fresh, fried, baked, or high-moisture/sugar bulk foods.

Real-World Impact: French fries – Identifies hair, scab disease, rot, or green heads with precision.

Equipment: Ultra-HD Multi-Beam Optical Sorter

Eliminates visual blind spots and enhances detection of color variations and defects.

High IP rating and easy-clean design for hygiene and maintenance.

6. Ultra-HD High-Protection System

For: Packaged products in demanding cleaning environments.

Equipment: IP69K Ultra-HD X-Ray Inspection System

Resists dust and high-pressure, high-temperature water/steam cleaning.

Excels at detecting fine contaminants and internal defects.

7. High-Speed Precision Weight Sorting

Equipment: Next-Gen High-Speed Checkweigher

Unmatched accuracy and smooth handling for stable, durable performance.

User-friendly 10-inch HD touchscreen and easy part replacement.

Space-Saving, High-Performance Equipment

8. Compact X-Ray System

50% smaller than standard models, perfect for tight spaces.

Simple operation, broad application range.

9. Compact Vision Inspection System

Compact design for seamless integration into any production line.

Checks inkjet characters, labels, barcodes, and QR codes on various packaging.

10. Combo Metal Detector and Checkweigher

Combines both functions in a single, space-efficient cantilever frame.

Ideal for existing workshops with limited space.

All-in-One Quality Control Solution

A powerful equipment lineup featuring ultra-HD X-ray, bulk sorting, and high-speed weight sorting for comprehensive quality assurance.

Copyright © 2021 Techik Instrument (Shanghai) Co., Ltd. All Rights Reserved.