In the modern food processing industry, optical sorting technology has revolutionized the way chili peppers are inspected and graded, significantly improving quality control and operational efficiency. This advanced technology utilizes high-resolution cameras and sophisticated image processing algorithms to meticulously analyze chili peppers as they traverse through the sorting line. Here’s how optical sorting optimizes the handling of chili peppers:

Precise Color and Quality Assessment: Optical sorters excel in discerning subtle differences in color and ripeness among chili peppers. They accurately distinguish between various shades of red, green, and other colors, ensuring that only vibrant and ripe peppers meet the stringent quality standards demanded by consumers and regulatory bodies alike. This capability not only enhances the visual appeal of the final product but also prolongs shelf life and reduces waste by removing visually unappealing or underripe peppers from the supply chain.

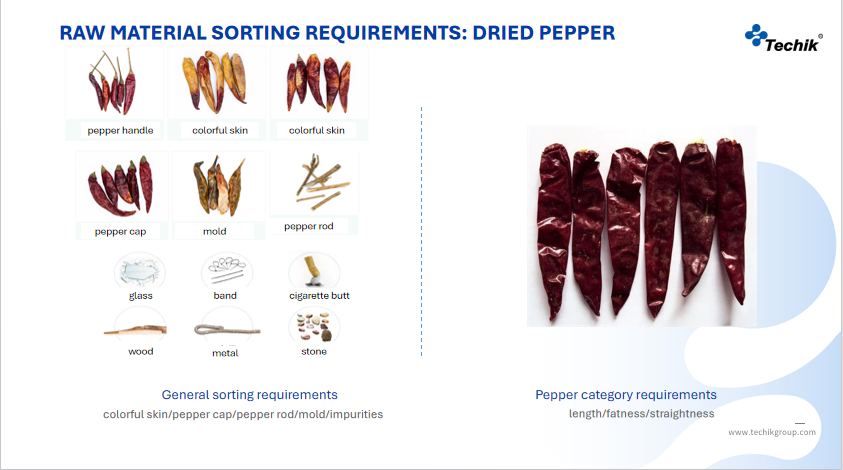

Size and Shape Consistency: Consistency in size and shape is crucial for uniform packaging and efficient processing. Optical sorters measure each chili pepper with precision, sorting them into predefined categories based on size criteria. This capability not only streamlines packaging processes but also facilitates consistent cooking times and presentation in culinary applications, meeting the diverse needs of both retail and foodservice sectors.

Defects and Foreign Material Detection: Detecting and eliminating defects such as bruises, cuts, or irregular shapes is essential to maintain product integrity. Optical sorting systems swiftly identify and remove defective peppers, ensuring that only high-quality produce reaches consumers. Moreover, these systems effectively detect and eject foreign materials like stems, leaves, or other contaminants, which may inadvertently enter the processing line, safeguarding against potential health risks and upholding food safety standards.

Enhanced Efficiency and Cost Savings: Optical sorters operate at high speeds, processing large volumes of chili peppers with unparalleled efficiency compared to manual sorting methods. This not only increases throughput but also reduces labor costs and minimizes the risk of human error. By automating the sorting process, food processors can achieve higher levels of productivity and operational reliability, thereby optimizing overall production efficiency and profitability.

Market Competitiveness and Compliance: In a competitive market environment, meeting consumer preferences and regulatory requirements is paramount. Optical sorting technology enables producers to grade chili peppers accurately according to industry standards and market demands. By delivering consistently high-quality products, processors can enhance their market competitiveness, build consumer trust, and expand market reach domestically and internationally.

Conclusion: Optical sorting technology represents a cornerstone of modern chili pepper processing, offering unparalleled capabilities in quality control, efficiency, and compliance with stringent industry standards. By harnessing the power of advanced imaging and sorting algorithms, food processors can ensure that every chili pepper meets the highest standards of quality, safety, and visual appeal, ultimately benefiting consumers, producers, and the entire food supply chain.

Copyright © 2021 Techik Instrument (Shanghai) Co., Ltd. All Rights Reserved.