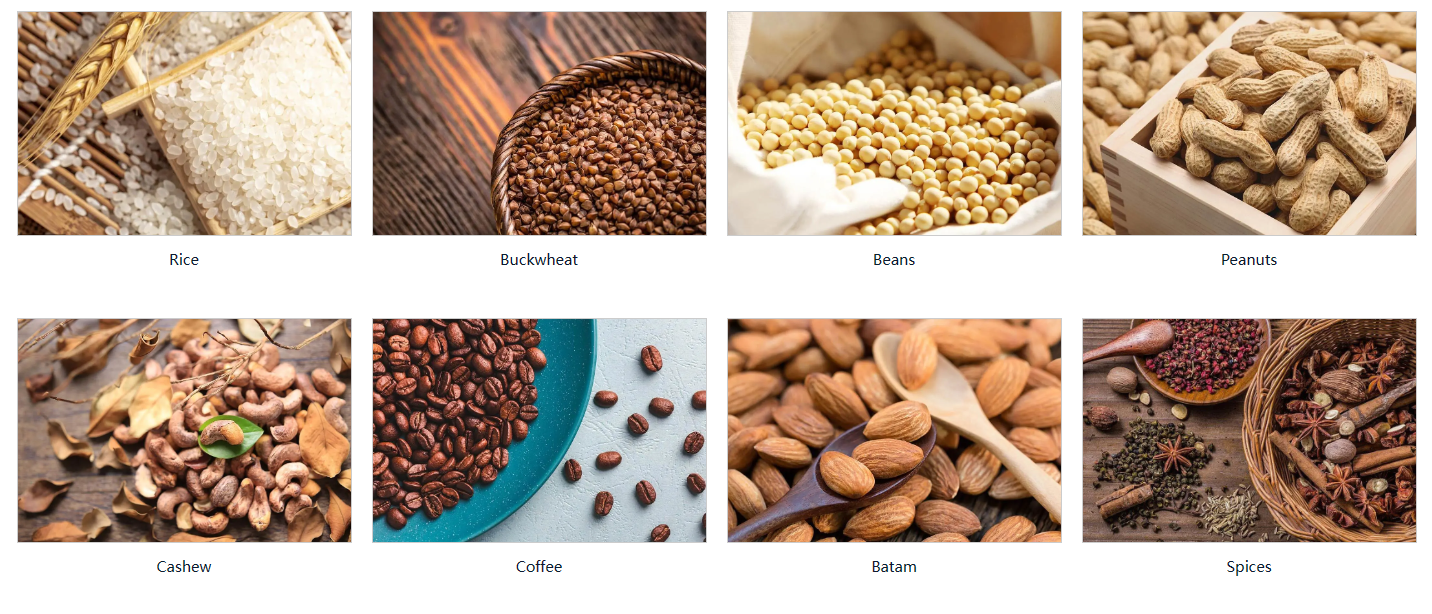

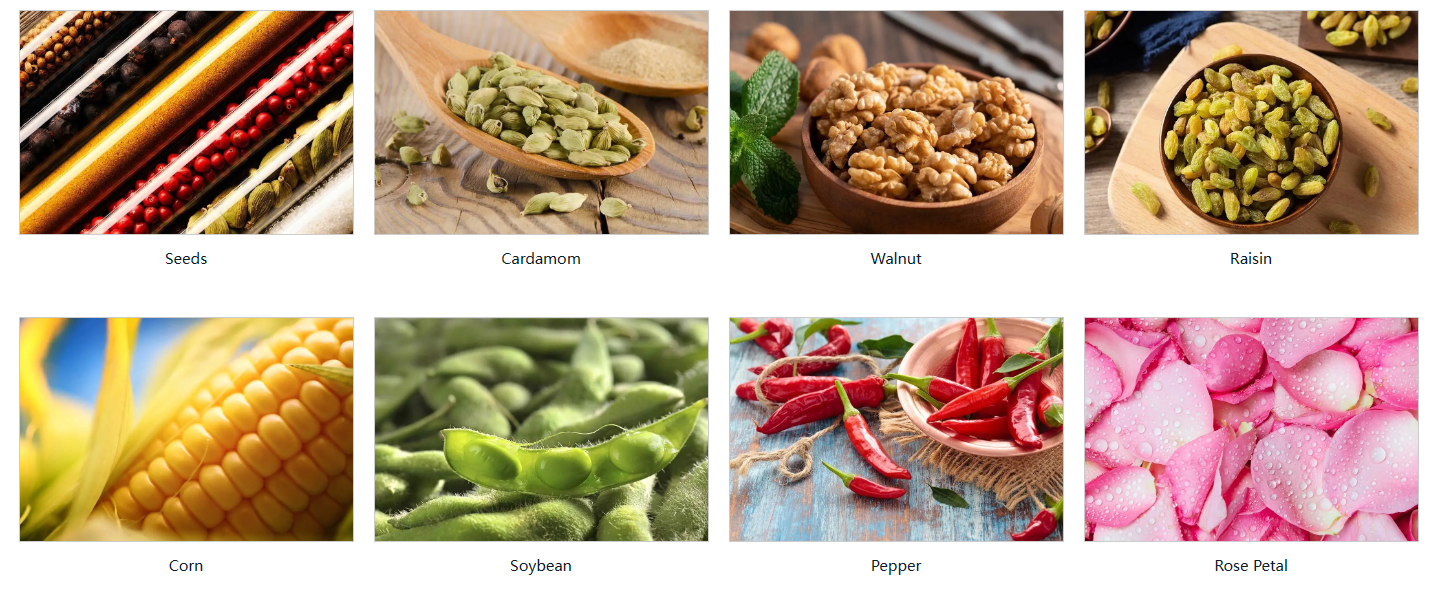

A color sorter is a highly sophisticated and technologically advanced device utilized across various industries, particularly in sectors like food processing, agriculture, and recycling. Its primary function revolves around the optical inspection and sorting of a wide array of items, encompassing grains, seeds, nuts, fruits, vegetables, plastics, and diverse materials, based on distinct criteria such as color, shape, size, and occasionally texture.

At its core, the color sorter operates through cutting-edge imaging technology, including specialized cameras and sensors, strategically positioned to capture detailed images of items as they traverse through the machine on a conveyor belt. These images are then subjected to intricate analysis within the system, leveraging powerful algorithms and software to discern and differentiate between objects according to predefined parameters and characteristics.

The sorting process itself is a testament to the machine's efficiency and speed. Upon analyzing the captured images, the color sorter swiftly identifies items that deviate from the established standards or criteria. To effectuate the sorting action, the machine employs precision-targeted mechanisms, such as jets of compressed air or mechanical arms, which are strategically positioned along the conveyor belt's path. These mechanisms either divert or remove the undesired items in real-time, ensuring that only those meeting the specified quality benchmarks continue along the processing line.

The overarching goal of deploying a color sorter lies in enhancing various facets of production and processing. One of its paramount functions is to bolster product quality by meticulously segregating items based on their defined characteristics. By doing so, it eliminates defects, foreign materials, or irregularities that might compromise the final product's quality, purity, or safety.

Moreover, the implementation of a color sorter significantly augments operational efficiency. By automating the sorting process, it expedites the pace at which items are inspected and sorted, thereby streamlining production lines and minimizing human error. This optimization of processes ultimately translates to increased productivity and reduced wastage, ensuring that only the highest-quality items proceed for further processing, packaging, or distribution.

In essence, a color sorter serves as a critical component in ensuring stringent quality control measures, enhancing food safety standards, and optimizing production workflows across diverse industries, contributing significantly to the overall efficiency and reliability of the manufacturing and processing sectors.

Copyright © 2021 Techik Instrument (Shanghai) Co., Ltd. All Rights Reserved.