The sorting process in coffee beans is a critical aspect of coffee production, ensuring that only the finest beans make it through to the final product. This process involves multiple stages, each designed to remove defects, impurities, and foreign objects that could negatively impact the quality and safety of the coffee. By utilizing advanced sorting technology, coffee producers can deliver a product that meets the high standards expected by consumers.

Stage 1: Sorting Fresh Coffee Cherries

The first step in the sorting process begins with fresh coffee cherries. Sorting at this stage is essential to remove cherries that are unripe, moldy, or damaged. Techik’s state-of-the-art sorting equipment, including intelligent double-layer belt visual color sorters, is used to detect and eliminate these defective cherries. This technology can identify subtle differences in color and texture, ensuring that only the best cherries proceed to the next stage of processing.

Stage 2: Sorting Green Coffee Beans

Once the cherries are processed and the beans are extracted, the next stage involves sorting green coffee beans. This step is crucial for removing defects that may have occurred during harvesting or processing, such as insect damage, mildew, or discoloration. Techik’s advanced sorting solutions, such as visual color sorters and X-Ray inspection systems, are employed to identify and remove these defects. Additionally, this stage also involves the removal of foreign objects like stones or shells, which could otherwise cause issues during roasting.

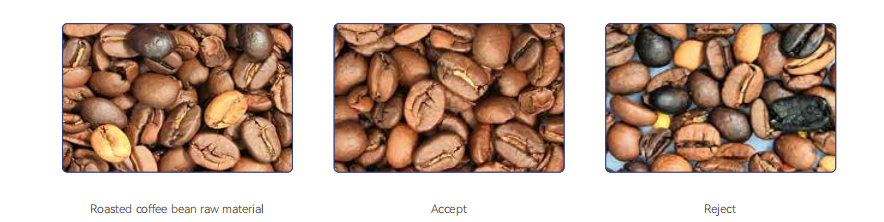

Stage 3: Sorting Roasted Coffee Beans

After roasting, the beans undergo another round of sorting to ensure that only the highest quality beans make it to the final product. Roasting can sometimes introduce defects like over-roasting or cracks, which need to be removed. Techik’s intelligent UHD visual color sorters and X-Ray inspection systems are specifically designed to detect and eliminate these defects. This step is vital for maintaining the quality and consistency of the roasted beans, ensuring they are free from impurities and imperfections.

Stage 4: Inspecting Packaged Coffee Products

The final step in the coffee bean sorting process involves inspecting the packaged products. This inspection is crucial for ensuring that the final product is safe and of high quality. Techik’s comprehensive inspection systems, including X-Ray machines and metal detectors, are used to detect any remaining contaminants or defects. These systems ensure that every package meets regulatory standards and is free from foreign objects, incorrect weights, or labeling errors.

Overall, the sorting process in coffee beans is a detailed and multi-faceted procedure that plays a vital role in ensuring the quality of the final product. By implementing Techik’s advanced sorting and inspection technology, coffee producers can ensure that their products meet the highest standards of quality, safety, and consistency, providing consumers with the best possible coffee experience.

Copyright © 2021 Techik Instrument (Shanghai) Co., Ltd. All Rights Reserved.