The X-Ray Inspection System for Fish Bone is a specialized equipment designed to detect and remove bone fragments from fish products during the production process. It utilizes X-ray technology to scan the fish for any bone fragments, ensuring that the final product is bone-free and safe for consumption. This system helps in improving product quality, reducing the risk of choking hazards, and ensuring compliance with food safety regulations.

Features

•Suitable for foreign contaminant and fish bone detection in fish meat, applicable to products such as halibut, salmon, and cod.

•Not only can it detect foreign contaminants in fish meat, but it can also be paired with an external high-definition display screen to clearly display various types of fish bones in cod, salmon, and other fish, helping manual removal of fish bones accurately.

•4K HD Screen

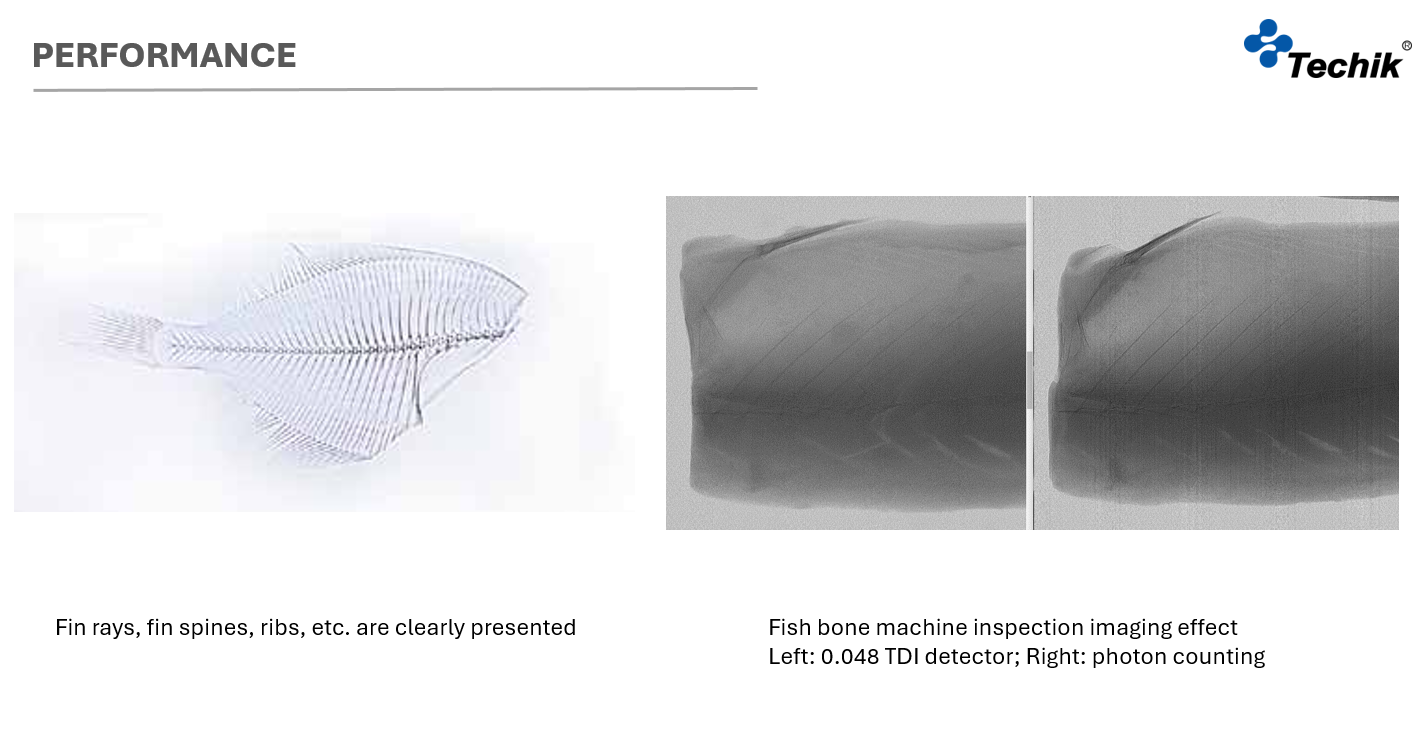

•Various detectors such as 0.048 TDI Detector and photon counting detectors

•Highly Waterproof Machine

The X-Ray Inspection System for Fish Bone finds application in various stages of fish processing, including:

Raw Material Inspection: It can be used to inspect whole fish or fillets at the receiving stage to ensure that the raw material is free from bone fragments before further processing.

Processing Line Integration: The system can be integrated into processing lines to inspect fish products after filleting or portioning, ensuring that bone fragments are removed before packaging.

Quality Control: X-ray inspection helps maintain consistent product quality by detecting even small bone fragments that may be missed by manual inspection.

Food Safety Assurance: By ensuring that fish products are bone-free, the X-ray inspection system contributes to food safety, reducing the risk of choking hazards and consumer complaints.

Regulatory Compliance: It helps processors meet regulatory requirements for food safety and quality control, ensuring compliance with industry standards and regulations.

Overall, the X-Ray Inspection System for Fish Bone plays a critical role in enhancing product quality, ensuring food safety, and meeting regulatory standards in the fish processing industry.

The features of an X-Ray Inspection System designed specifically for fish bone detection typically include:

High-Resolution Imaging: Capable of producing detailed X-ray images of fish products to accurately detect bone fragments, even those as small as a few millimeters.

Customizable Detection Parameters: Allows operators to adjust sensitivity levels and inspection parameters to suit different types of fish products and production environments.

User-Friendly Interface: Intuitive user interface with touchscreen controls for easy operation and monitoring of the inspection process.

Hygienic Design: Constructed with food-grade materials and designed to meet hygiene standards, facilitating easy cleaning and maintenance.

Multi-Lingual Support: Supports multiple languages for user interface and operator instructions, catering to diverse workforce requirements.

High-Speed Inspection: Capable of inspecting fish products at high speeds without compromising detection accuracy, ensuring minimal impact on production efficiency.

These features collectively enable the X-Ray Inspection System for Fish Bone to effectively detect and remove bone fragments from fish products, ensuring consumer safety, product quality, and regulatory compliance in the food processing industry.

Copyright © 2021 Techik Instrument (Shanghai) Co., Ltd. All Rights Reserved.