During China Nut and Roasted Seeds Industry Exhibition 2021, Shanghai Techik was interviewed by Anhui Television. Techik staff showed the sunflower seed inspection and sorting process to the reporter. As shown in the video, the sunflower seeds were added in material feeding part of Techik Intelligent Belt Color Sorter. The Techik intelligent production line which was combined by X-ray inspection machine and color sorter detected and sorted the sunflower seeds.

Seed kernel solution

The combination of intelligent color sorter, intelligent X ray inspection system, which take advantage of unique optical path design and powerful intelligent algorithm, can accurately and efficiently detect and reject wormhole, flower skin, empty shell, thin sheet plastic, thin sheet glass, mud block, stone, bandage, button, cigarette butts, sunflower plate, straw, nodule, Xanthium, animal dung ball, insects and other impurities.

Peanut sorting solution

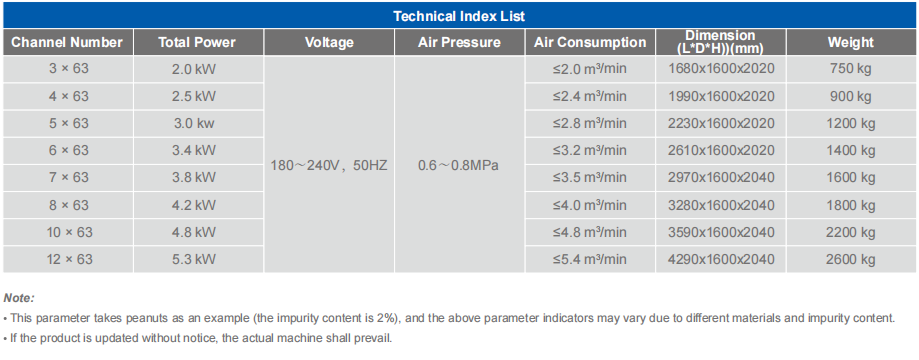

Shanghai Techik upgrades the original peanut sorting solution and grandly introduces the upgraded peanut sorting solution in 2021. In the newly-introduced solution, besides the original TCS series color sorter, intelligent chute color sorter, intelligent crawler color sorter and seed kernel color sorter are also used to sort color, shape and impurity. When intelligent X-ray inspection system for bulk product is added, malignant impurities can also be detected. That is, foreign bodies and bad products such as frozen peanut, rusty peanut, short bud, mildew peanut, disease spot, long round peanut separation, half peanut, peanut with mud, shell damaged peanut, embedded steel sand peanut, peanut rod, thin sheet plastic, thin glass, mud block, stone, tie belt, button, and cigarette butts, which are common found in peanut industry, can be accurately and efficiently detected and rejected by Techik’s new peanut sorting solution.

Batam sorting solution

Aiming to solve the pain points, such as wormhole, double nut kernels, dry nut, fold nut, half nut and broken nut, in nuts industry, Shanghai Techik newly launches perfect batam sorting solution, in which customers can choose one or some of the following equipment to deal with their problem: intelligent color sorter, intelligent crawler color sorter, seed kernel intelligent color sorter, wormhole powder X ray machine, and intelligent X-ray inspection system for bulk product. At present, the solution is so mature that it is widely used and verified in the market and widely praised by industry customers.

1. Intelligent setting: simple setting, completed within 5 minutes

2. Intelligent algorithm, with accurate and stable effect

3. DIY your own selection classification, done by one click

1. High-definition 5400 pixel full-color sensor

2. High-brightness LED cold light source

3. High-frequency solenoid valve, intelligent algorithm tracking, precise rejection

4. Optional smart dust collection system, which can automatically clean up the dust in the feed and prolong the life of the equipment

1. Intelligent monitoring of background data, remote setting & bug locking

2. Data visualization, storage integration, and one-click replacement of popular programs

3. Big data, cloud storage, free download

1. 4-5 Times better in exposure compared with standard 0.4mm detector.

2. Higher sensitivity, longer service time, low radiation and maintenance cost.

1. Easy installation and setting.

2. Remote setting is possible.

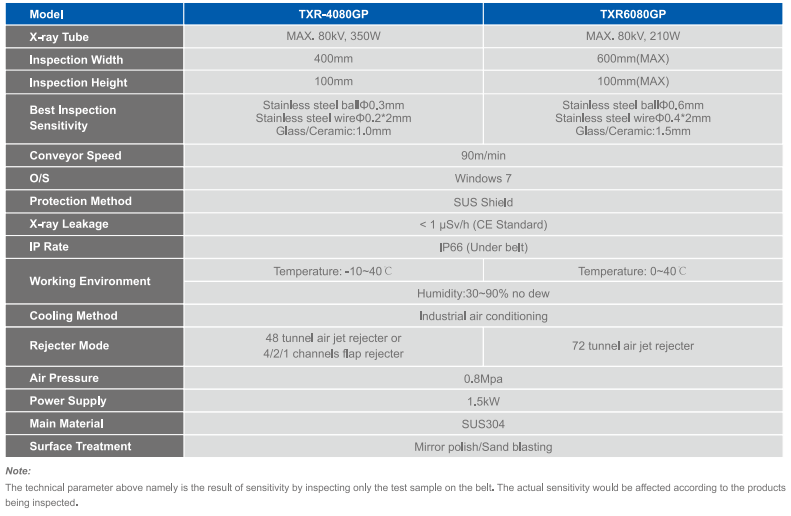

1. Different configuration based on different requests

2. Various rejecter systems

Copyright © 2021 Techik Instrument (Shanghai) Co., Ltd. All Rights Reserved.