In food and drug manufacturing and food processing industry, in order to ensure product quality and control quality cost, testing link is essential for quality management.

There are two defects for traditional test link in these enterprises. One is adopting artificial quality inspection, which costs high but however cannot be applied into the mass production line for the low speed and accuracy. The other is traditional testing equipment, which can only be used for simply and single type defect inspection.

How to replace artificial labor with machinery to improve the efficiency and accuracy of complex defect detection? Deep learning algorithm technology has been developed rapidly to be integrated into the production line, to efficiently complete the detection task of complex defects.

Deep learning algorithm with thousands of layers of neural network, simulate people's thinking process and behavior. Combined with optical devices and sensors, inspection machine with deep learning algorithm can simulate artificial recognition analysis image, detect features difficult to quantify, and irregular defects. Take germination peanut as an example. The bud of germination peanut in shape is not the same, in quality is difficult to count, so the traditional algorithm is difficult to cope with. But intelligent detection equipment with deep learning algorithm can identify the subtle differences, distinguish germination peanuts and normal peanuts.

Compared with manual inspection, the intelligent detection equipment based on deep learning algorithm has a wider range of visual perception, and is greatly improved in speed, accuracy, environmental adaptability and other aspects, which can quickly integrate into high-speed and high-yield automated production lines.

Techik is committed to the research of spectral online detection technology, and applies deep learning algorithms to food detection and food sorting. For different products, Techik can also solve the detection problems for customers via personalized solutions and configuration.

Deep learning + X-ray detection

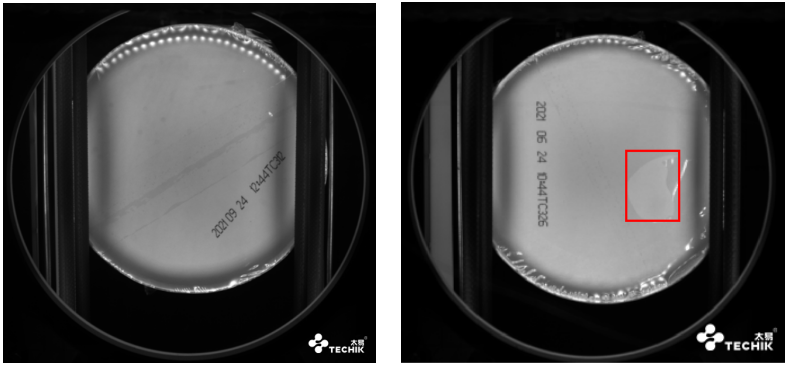

Techik intelligent X-ray inspection machine applies deep learning algorithm to effectively improve the detection accuracy. In addition to the conventional foreign body detection function, it can also detect complex quality problems such as manual leakage, ice cream crack, cheese bar missing, oil leakage and clip of small package food sealing.

Deep learning + food sorting

Techik intelligent visual sorting machine with deep learning algorithm, can learn from nuts, seed kernel, Chinese herbal medicine, pepper, such as material shape, color, texture characteristics, and then accurately identify the irregular spots / color block, irregular shape, subtle shape, and color differences such as complex defects. Techik color sorters can also meet different customer demand, personalized defining defect range to meet the requirements of different raw material classification.

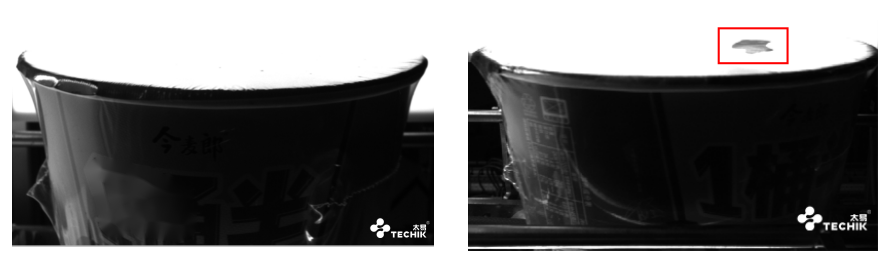

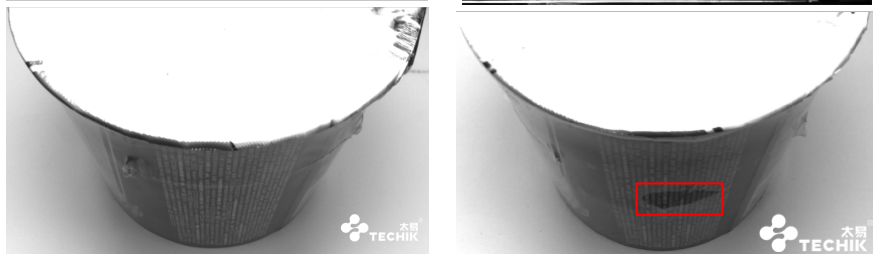

Deep learning + outer packaging defect detection

Techik intelligent visual detection machine can carry out 360 defect detection on the thermal shrink film packaging of bucket instant noodles surface and other products, and can also customize code injection detection, high slanting cover detection, liquid level detection and other solutions according to customer needs, aiming to solve practical problems for production enterprises, improve production efficiency and product quality.

Copyright © 2021 Techik Instrument (Shanghai) Co., Ltd. All Rights Reserved.